Let’s learn more about UV varnish

2019-11-20 17:19:33

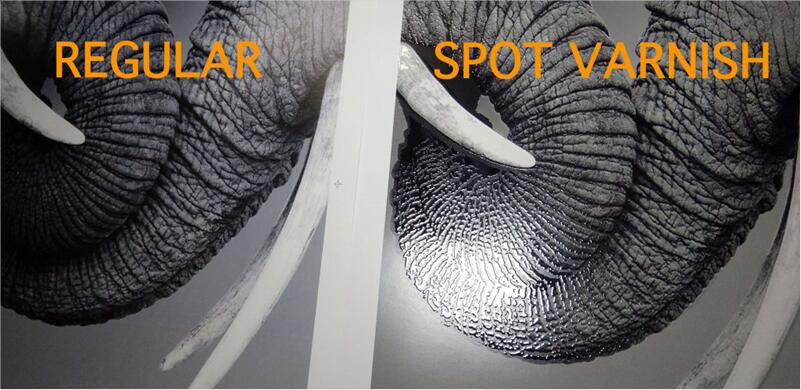

· What is UV varnish?

UV varnish is a transparent curing.

Its function is to spray or roll on the surface of the substrate, after being irradiated by UV lamp, it is converted from liquid to solid, thereby hardening the surface and scratch resistance, making the surface looks bright, beautiful and rounded.

UV curing is a photo-chemical reaction in which a liquid UV-irradiated curable material is printed or coated onto a substrate or work piece surface and cured by UV light.

Screen printing, offset printing, and 5-color printing mostly use irradiation with fast drying, good adhesion, various performance standards (adhesion, abrasion resistance, etc.) to convert from liquid to solid to achieve surface hardening.

· Features of the UV varnish:

1. Excellent adhesion. During the test, the 3M tape was pulled three times at the same place, and the UV varnish did not drop.

2. High gloss, smoothness and leveling. It has the characteristics of fine film formation and good hand feeling. The gloss is above 85 degrees.

3. Fast curing speed. For example, under the premise of sufficient energy of the UV machine, the speed can reach 8000 sheets of paper per hour, which greatly saves time.

4. UV varnish can reduce energy consumption. Because of its high solid content, the emission of voc is reduced to a great extent, which is suitable for improving production efficiency and reducing energy consumption thus to reach the requirements of green and environmental protection.

· Cautions of using the UV varnish:

1. The normal operating temperature of UV varnish is 50-55 °C. When in winter and there is low temperature, it is necessary to use thermos tatted water to heat the UV varnish to make the viscosity reach the designed one which is beneficial to the smoothing and curing of UV varnish rapidly.

2. The glazing machine should be placed in a position where the sunlight cannot be directly irradiated; otherwise the UV varnish will be solidified on the coating roller under the action of ultraviolet light in the sunlight. If you can’t avoid direct sunlight, you should hang red and black curtains to block the sun’s rays.

3. With the development of science and technology, the irritancy of UV varnish has been greatly reduced. However, if the skin is exposed to UV varnish during glazing operation, it should be washed off immediately with soapy water, otherwise redness and blistering may occur.

· Auber’s concerning on UV varnish:

We are constantly pursuing innovation and progress, so we have recently introduced a new machine for UV varnish, which also increases our production efficiency. To our aim, UV varnish greatly reduces our energy consumption, which is the green production goal we have been advocating.

Not only had that, but the use of UV varnish also improved the quality of our products. In particular, its strong adhesion makes the printing on the tubes not easy to be scratched and drop and better protects the print design of customers who use it for a long time. Moreover, users can feel good and comfortable about the tube itself.

We believe that with the development of technology in the future, the cosmetic tubes industry will have more room for improvement, bringing more comfortable and beautiful experiences to users.