Comparison of Paper Packaging and Tube Packaging

2020-01-22 10:38:38

Printing is widely used in packaging, because of the increasing market competition, it is necessary to constantly bring forth new ideas to attract the attention of consumers. Therefore, many customers will appropriately increase the cost of outer packaging, but in the same time it increase the difficulty of making higher value packaging with various design and decoration.

What printing ways will the paper packaging normally be done?

1) Offset printingcommonly using the CMYK and Pantone colors, because the complex and colorful patterns are more likely to attract people’s visual attention,and more attention will be paid to the packaging products. According to different kind of paper, the requirements of printing are different. For example, the pearl paper and touch paper, theirsurfaces aretoo smooth and it is difficult to absorb printing inks,generally it will use the silk screen printing.

Usually after printing, to prevent the printed designs from being worn out in the production, the surface will be done with matte /glossy film or matte/ glossy oil. If you want the paper to be felt morehigh-end or colorful, you can also go through the touch film or laser film on it.

2) Silk screen printing in the paper packaging industry. If the artwork with extremely fine font or line, we generally recommend the customers to enlarge the font or some part to silk screen printing. Of course, based on the material of paper, different Paper also has a special impact on the printing effect.

Silk screen printing is also widely applied to PVC assome customers who want to add a transparentPVC window on the box and print logo or something on it.At this time, silk screen printing will be chosen.

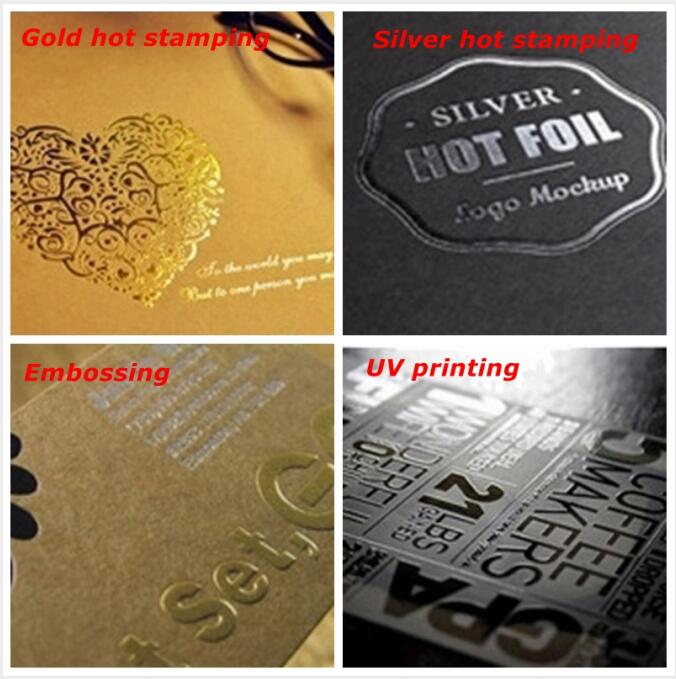

In order to make the design or logo on the box/bag more attractive, Spot UV, hot stamping and embossing usually will be advised.

How plastic tube packaging print?

It is mainly divided into two categories: one is produced by extrusion before printing, that is PE tube, the other is to print laminated film (or composite sheet) first before making tubes, which is mainly used for all plastic barrier laminated tubes (PBL) and aluminum barrier laminated tubes(ABL) , and the printing method is mainly offset printing and silk screen printing.

Plastic tube packaging,PE tubes are produced by extrusion.A sleeve is first produced on a specialized extrusion machine. It must be produced to a very high standard (for decoration purposes) and also to tight tolerances, compatible with automated processes after extrusion. Once the sleeve is produced, the tube head is fitted using an automated heading machine.Tube printing using specialized printing machines such as silk screen printing and offset printing applies the desired decoration. The offset printing machine can print 8C and the silk screen machine 6C at most. The open tubes are typically filled and sealed at a separate facility. Multi-layer PE tubes have become increasingly popular; they isolate the contents better from the air, allowing them to be used for a wider range of products, such as food.

After silk screen printing, the logos or designs will let you feel a little embossing by touching, and offset printing can print more colors and complex patterns.

Spot UV or hot stamping is mostly used on the tube logo or designs to make it more high-end and elegant.

Plastic tubes are popular for cosmetics such as hand creams, and also some foodstuffs. The plastic tube retains its shape after each squeeze unlike laminate tubes such as toothpaste tubes. Plastic tubes can be highly decorated or have a special additive such as soft touch to make the tube more appealing during use or at the point of sale.

Nowadays, people has attached more importance to green material tubes and it has been a trending, PCR material and green PE material are starting to laminated into PE tubes packaging now, but it still the laminated sheet, maybe not be very biodegradable, how to be more recyclable and biodegradable?

Any interest?Pls feel free to check with us.

Original post by Ruby

https://www.linkedin.com/pulse/comparison-paper-packaging-plastic-tubes-ruby-huang/

Auber specializes in manufacturing cosmetic tubes for more than 16 years. If you need any support in plastic squeeze tubes for cosmetics, skin care, hair care, makeup, pharma,etc, welcometo visit our website www.cosmetic-tube.com and contact ruby@cosmetic-tube.com.